Japanese knife steels are well-known for their amazing sharpness and long-lasting edges. If you’re curious about what makes these knives special, it all comes down to the steel used to make them. The blades of Japanese knives are meticulously crafted, and the quality of the steel plays a crucial role in their exceptional performance, durability, and ability to achieve and retain sharpness. The kind of steel affects how sharp the blade is, how long it stays sharp, and how easy it is to keep it in good shape. Whether you’re a home cook or just someone who appreciates a good knife, knowing about Japanese knife steels can help you pick the right one.

- What Is Steel and Why Does It Matter?

- Kitchen Knife Materials

- Carbon Steel: The Classic Choice

- Stainless Steel: Easy to Care For

- Damascus Steel: Beauty and Strength

- Heat Treatment: What Makes the Steel Work

- Edge Retention and Sharpness

- Common Elements in Japanese Knife Steels

- Traditional Steel: Tamahagane and Sword Making

- Choosing the Right Steel for You

- Taking Care of Your Japanese Knife

- Final Thoughts

- FAQs About Japanese Knife Steels

What Is Steel and Why Does It Matter?

Steel is basically an alloy of iron and carbon. The amount of carbon and other metals added changes how the steel behaves. More carbon usually means harder steel, which can hold a sharper edge but might be a bit more fragile. Japanese knives often use special blends of steel that give them their unique qualities. These blends include elements like chromium, tungsten, vanadium, and molybdenum, which improve properties such as toughness and resistance to rust. Different alloy combinations result in unique properties that directly affect knife performance.

Kitchen Knife Materials

Materials matter.

Big time.

Want a great kitchen knife? The steel makes all the difference. Japanese kitchen knives are the real deal. They’re sharp. They stay sharp. They’re quality through and through. Why? It’s all about the steel they choose.

You’ve got three main types. Carbon steel. Stainless steel. High carbon steel. Each one does something different.

Carbon steel is the sharpening champion.

It gets razor-sharp fast. Stays that way too. Chefs love this stuff. Why? Easy to sharpen. Cuts like a dream. Precise every time. High carbon steel takes it up a notch. More carbon means more hardness. More hardness means longer-lasting sharpness. Want edge retention? This is your steel.

Stainless steel plays a different game.

Rust resistance is its thing. Perfect for busy kitchens. Great for home cooks who want easy care. Less fuss. Less worry. Sure, it might not get as sharp as pure carbon steel. But it’s reliable. It’s durable. It gets the job done.

Each steel brings something to the table.

Carbon steel? Easy sharpening. Stainless steel? Low maintenance. High carbon steel? Edge retention king. Choosing a Japanese kitchen knife? Think about the material first. Find your balance. Sharpness versus durability. Performance versus care. Match it to how you cook.

The choice is yours.

Carbon Steel: The Classic Choice

Carbon steel is a favorite for many Japanese knives. It contains more carbon than regular steel, which makes it hard and able to keep a sharp edge for a long time. Pure carbon steel is what samurai swords—also known as Japanese swords—were made from long ago, and it’s still prized by Japanese bladesmiths today, thanks to the tradition of Japanese bladesmithing that influences modern knife craftsmanship. The downside is that carbon steel can rust if you’re not careful, especially when it touches acidic foods like lemon or tomatoes. But if you clean and dry it right after use, it can last forever. During manufacturing, carbon steel is carefully hardened to improve its durability and edge retention, making it ideal for high-performance knives.

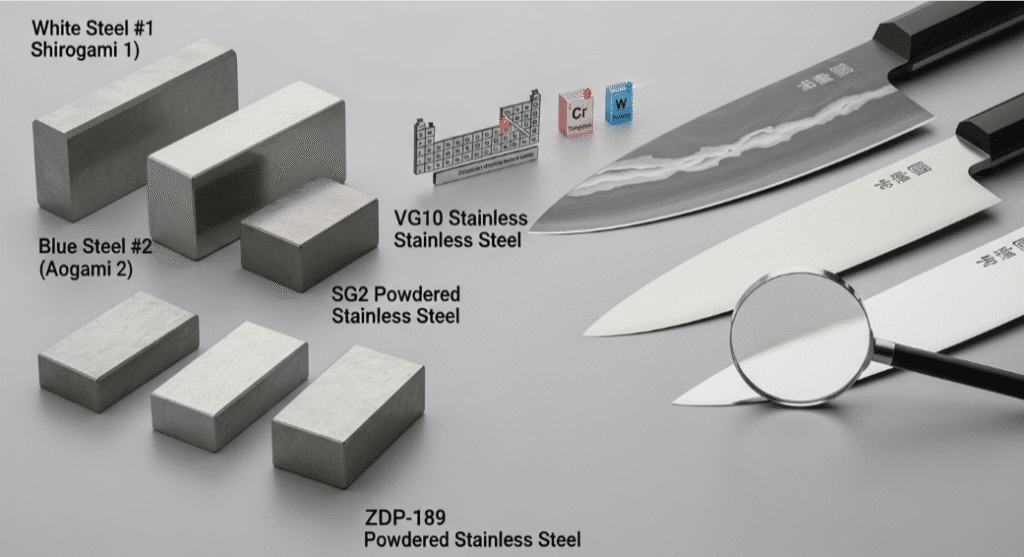

White Steel (Shirogami)

White steel is a type of carbon steel that’s very pure and simple. White steel is often used in honyaki knives, which are crafted from a single piece of high-carbon steel, showcasing traditional craftsmanship and superior quality. It doesn’t have many extra metals added, which makes it easy to sharpen and able to get extremely sharp. It can rust more easily, so you need to keep it dry. It’s perfect for those who want a really sharp blade and don’t mind a bit of extra care.

Blue Steel (Aogami)

Blue steel is similar to white steel but has added chromium and tungsten. These metals make the blade tougher and better at resisting rust. Blue steel knives hold their sharp edge longer and are less likely to chip. There are different grades of blue steel, like Blue #1 and Blue #2, with Blue #1 being harder and sharper but also a bit more delicate. Blue Super is a premium, highly hardened carbon steel used in top-tier Japanese knives, known for its superior performance and exceptional edge retention.

Stainless Steel: Easy to Care For

Stainless steel has chromium added in amounts over 12%, which helps stop rust and corrosion. Stainless steel is one of the most common steels used in Japanese knife making due to its durability and ease of maintenance. This makes stainless steel knives easier to maintain, especially if you’re busy or don’t want to worry about rust. They might not get as sharp or hold their edge as long as carbon steel knives, but they’re still great for everyday use.

VG-10 Steel

VG-10 is one of the most popular stainless steels used in Japanese knives. It has a good balance of hardness, sharpness, and corrosion resistance. It’s also easier to sharpen compared to some other stainless steels, which is great if you don’t want to spend a lot of time maintaining your knife.

Powdered Stainless Steels

Powdered steels like SG2 (also called R2) and ZDP-189 are high-tech alloys made by mixing metals at a microscopic level. Some of these high-quality powdered steels, such as SG2 and ZDP-189, are produced by Hitachi Metals, a renowned Japanese steel manufacturer. These steels are very hard and hold their edge for a long time. They’re tougher to sharpen but offer top-notch performance. Knives made with these steels are usually pricier and made by skilled craftsmen.

Damascus Steel: Beauty and Strength

Damascus knives are made by layering different types of steel and folding them together. This creates a beautiful, wavy pattern on the blade. The layering also adds strength and toughness. The manufacturing process is crucial for achieving the strength and unique appearance of Damascus knives. The sharpness depends on the core steel used, often a high carbon or powdered steel. Damascus knives are popular for their style and performance, but they can be more expensive because of the work involved in making them.

Heat Treatment: What Makes the Steel Work

Heat treatment is the process of heating and cooling the steel to change its hardness and toughness. The heat treatment process, also known as heat treating, is a crucial step that determines the steel’s final hardness and toughness. Japanese craftsmen use special heat treatment methods to get the best balance. A well-treated and properly hardened blade will be hard enough to keep a sharp edge but tough enough to avoid breaking easily.

The Rockwell Hardness Scale (HRC) measures how hard the steel is. Japanese knives usually range from 58 to 66 HRC. Harder knives stay sharp longer but can chip if used roughly. Softer knives are easier to sharpen and more forgiving but need more frequent sharpening.

Edge Retention and Sharpness

One of the reasons people love Japanese knives is their edge retention—the ability to stay sharp after lots of use. High carbon steels like Aogami Super are known for excellent edge retention. The cutting edge of Japanese knives, especially those made with advanced steels, delivers superior cutting performance and durability. The sharpness also depends on the blade’s shape and angle. Japanese knives often have a sharper angle than Western knives, making them cut cleaner. This long-lasting sharpness is also due to the higher hardness levels found in Japanese steels.

Keeping the edge sharp means regular maintenance. Honing helps realign the edge, while sharpening removes tiny bits of metal to restore the blade’s shape. Even the best steel needs some care to perform well.

Common Elements in Japanese Knife Steels

Japanese knife steels often include a mix of metals to improve their qualities. Different steel types in Japanese knives use unique combinations of these elements to achieve specific performance characteristics:

- Chromium: Helps resist rust and corrosion.

- Tungsten: Adds strength and helps the blade hold its edge.

- Vanadium: Increases hardness and wear resistance.

- Molybdenum: Improves toughness and corrosion resistance.

These elements work together to give Japanese knives their sharpness, durability, and corrosion resistance.

Traditional Steel: Tamahagane and Sword Making

Tamahagane is the traditional steel made from iron sand, used for making samurai swords. It’s very pure and has a high carbon content, which makes it extremely hard and sharp. Japan is renowned for its high-quality steel and exceptional craftsmanship, with Japanese people preserving and perfecting traditional sword making techniques over generations. Although it’s mostly used for swords, some high-end kitchen knives use tamahagane or steel inspired by it. The sword making process involves folding and hammering the steel many times to remove impurities and create layers. This technique influences how Japanese knife steels are made today.

Choosing the Right Steel for You

The best steel depends on how you plan to use your knife and how much care you want to give it. When selecting the appropriate Japanese knife steel, it’s essential to consider the intended use of the knife and your skill level. Different steels and knife types are better suited for specific culinary tasks and users, from beginners to professional chefs.

- If you want a blade that gets very sharp and holds its edge for a long time, carbon steel like blue steel or Aogami Super is a great choice.

- If you prefer something easier to maintain and resistant to rust, stainless steel like VG-10 or powdered steels might be better.

- For a knife that looks stunning and performs well, Damascus steel is worth considering.

Think about what you’ll be cutting, how often you’ll use the knife, your skill level, and whether you’re comfortable with regular sharpening and cleaning.

Taking Care of Your Japanese Knife

No matter what steel you choose, taking care of your knife will keep it performing well.

- Always hand wash your knife and dry it immediately to prevent rust.

- Use a sharpening stone or professional service to keep the edge sharp.

- Store your knife safely, like in a knife block or on a magnetic strip.

- Avoid cutting on hard surfaces like glass or stone, which can dull the blade.

Final Thoughts

Japanese knife steels are crafted with care and tradition, offering options that suit different needs and preferences. Japanese chef knives are known for their durable construction and the variety of steel types used, each providing unique benefits. From pure carbon steel to high-tech powdered alloys, each steel type has its own strengths. Knowing a bit about these steels can help you pick a knife that feels right for you and lasts a long time. Whether you want a razor-sharp edge, easy maintenance, or a beautiful blade, Japanese knives have something to offer.

Happy cooking and cutting!

FAQs About Japanese Knife Steels

Why do Japanese knives stay sharp longer than others?

It mostly comes down to the steel. Japanese knife steels often have more carbon and special metals like vanadium and tungsten. These make the blade harder and better at holding a sharp edge. The higher carbon content and use of hard steel give Japanese knives superior edge retention, as these properties make the blade both durable and responsive to sharpening. Plus, the way the steel is heat treated helps keep the edge tough without breaking.

Are carbon steel knives hard to take care of?

They need a bit more attention than stainless steel. Carbon steel can rust if it’s not dried right after use, especially if it touches acidic stuff like lemon or tomatoes. But if you clean and dry it well, it lasts a long time and gets really sharp.

What’s the deal with Damascus knives? Are they better?

Damascus knives look cool because of the layered steel pattern, but the real deal is the core steel inside. If the core is good quality, the knife will perform well. The layers add strength and style, but don’t always mean better sharpness or durability on their own.