If you’re looking for a sharp, reliable knife, an Echizen Japan knife might just be what you need. These knives are known for their sharpness and toughness, making them a favorite among both home cooks and professional chefs. What makes Echizen knives special is their long history and the skill that goes into making each one. They come from Fukui Prefecture in Japan, where skilled artisans use time-tested forging techniques and carefully chosen materials to craft blades that last. Echizen knives are crafted using traditional Japanese forging techniques and manual polishing steps, ensuring their exceptional quality and durability. Echizen Uchihamono is recognized for its unique double-layered and rotational steel forging techniques, which contribute to the knives’ exceptional performance and durability.

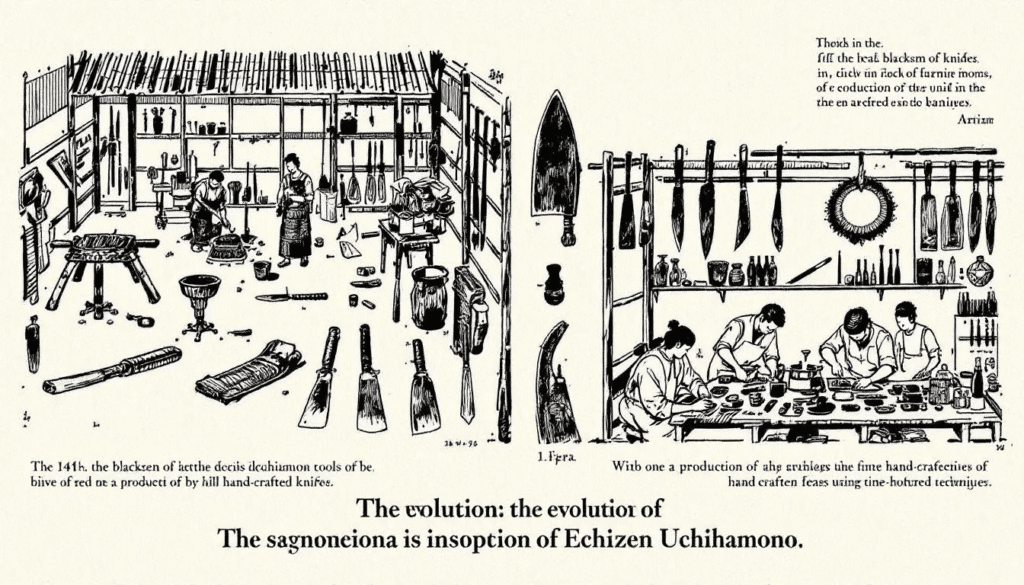

History of Echizen Uchihamono

The story of Echizen Uchihamono goes back to the 14th century in Echizen City. Originally, the craftsmen made farming tools like sickles. Echizen’s blade-making tradition dates back to the 14th century when Kuniyasu Chiyozuru began crafting tools for farmers. Over time, they shifted to making forged knives while keeping their traditional methods alive. Echizen Uchihamono refers to the handcrafted metal tools and knives produced in Echizen City. The Japanese government recognized Echizen Uchihamono as a traditional craft in 1979, showing how important it is to Japan’s culture. Today, the craft is still alive, with artisans teaching their skills to the next generation.

Craftsmanship and Forging Techniques

Echizen knives are made using old-school forging methods combined with some modern ideas. The artisans use carbon steel, known for its strength and sharpness, and work the metal with heat and hammering to shape the blade. This process gives the knives a sharp edge that holds up well and resists rust. The rotational steel forging method creates blades that are thin, durable, and easy to sharpen. The double-layered technique involves layering two sheets of metal and hammering them into shape, further enhancing the blade’s strength and sharpness. The blades are light and balanced, which makes them easy to handle. Each knife feels comfortable in your hand and is built to last.

Materials and Construction

Most Echizen knives use high-quality carbon steel. This steel is picked carefully for its ability to stay sharp and resist wear. The knives go through a process of forging, shaping, and polishing, mixing traditional and modern steps. Many Echizen knives are crafted to be very thin and light, reducing user fatigue during long cooking sessions. To keep your knife in good shape, it’s best to hand wash it with mild soap and dry it right away. This helps stop rust and keeps the blade sharp. The knives also have a thin spine and a well-thought-out shape, so they’re simple to use and control. Mud quenching, a traditional hardening process where a blade is coated in mud, heated, and then rapidly cooled in water, is often used to increase the hardness of these knives.

Takefu Knife Village

Takefu Knife Village is where many Echizen Uchihamono artisans live and work. This village is all about keeping the traditional craft alive and passing it on. If you visit, you can watch the craftsmen at work and see how much skill goes into each knife. Authentic Echizen knives can be purchased directly from artisan workshops in Takefu Knife Village. Specialized Japanese cutlery stores also sell authentic Echizen knives, ensuring that customers can access these high-quality tools. The village also has shops and restaurants, making it a cool place to learn about Echizen knives and Japanese culture.

Echizen City and Its Role in Knifemaking

Echizen City has been making blades for hundreds of years. It’s home to many artisans who still use the old techniques to make top-quality knives. Echizen knives transitioned from agricultural tools to exquisite kitchen knives over time. The city also welcomes new ideas and materials, blending tradition with innovation. Lacquer tappers relied on high-quality tools from Echizen for harvesting resin, which expanded Echizen’s reputation for producing exceptional metal tools. This mix of history and creativity makes Echizen City a unique spot for anyone interested in knives and Japanese culture.

Uses of Echizen Knives

Echizen knives are great for many tasks—whether you’re slicing, dicing, chopping, or mincing. They work especially well in the kitchen, where sharpness and durability matter. Echizen knives allow for thin, precise slices of vegetables and fish, which is fundamental to Japanese cutlery. The yanagiba is a long, thin, single-beveled knife strictly for slicing fish to make sashimi and sushi, showcasing the precision and sharpness of Japanese cutlery. People also use them outdoors for camping or hunting because they’re strong and dependable. Whether you’re a pro chef or just enjoy cooking at home, an Echizen knife can be a solid choice.

Preservation of Traditional Craft

Keeping the traditional craft going is key to making sure Echizen knives stay top quality. The artisans work hard to teach their skills to younger folks. Echizen knifemaking began with Kuniyasu Chiyozuru, who forged sickles for local farmers. They stick to using traditional materials like carbon steel and old forging methods. Yoshimi Echizen knives are designed, forged, and sharpened in one workshop in Echizen, ensuring a high level of craftsmanship and attention to detail. Supporting these craftsmen helps keep the Echizen knife tradition alive for years ahead.